Hi @Potato

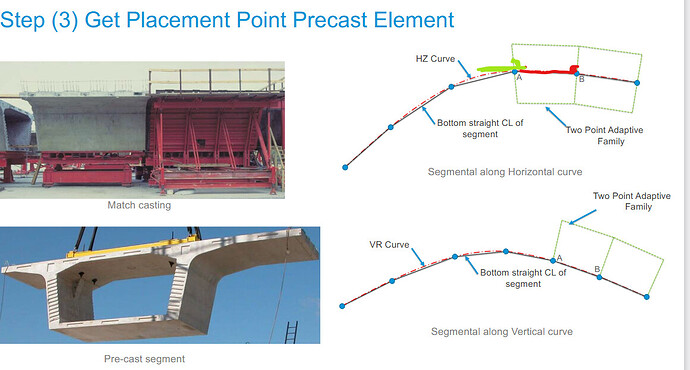

Your idea of cutting a solid to match the geometry for the short match technique, commonly used in segmental bridge construction, is interesting.

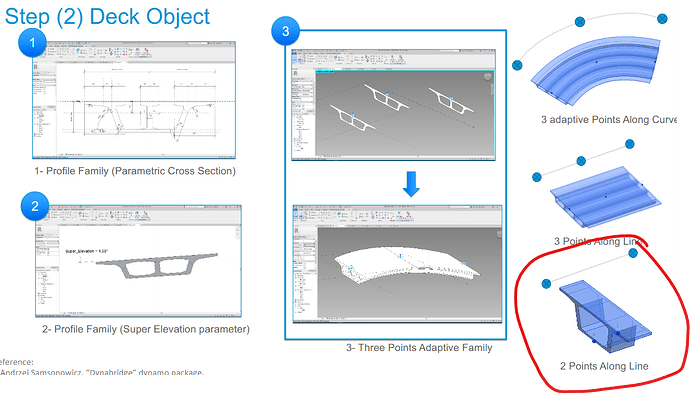

However, I would recommend using a two-point adaptive family instead of cutting the solid directly. This method offers greater flexibility and accuracy, especially for complex bridge alignments.

Here’s how it works:

-

The two-point adaptive family is driven by two reference points:

-

Point A represents the bridge cross-section (typically the bulkhead), and should be oriented perpendicular (90 degrees) to the segment’s centerline.

-

Point B should be aligned perpendicular to the bridge alignment, ensuring correct positioning along curves and transitions.

-

-

Additionally, it’s important to rotate the cross-section so that it remains perpendicular to the vertical profile — this ensures accurate placement and fabrication-ready geometry.

Rotate Element on Z axis perpendicular curve - #9 by RMohareb

This method aligns well with the short match technique and can be integrated easily into a parametric or automated BIM workflow using Revit and Dynamo.

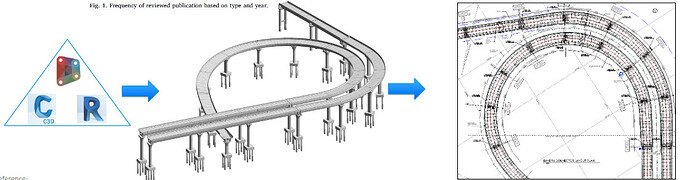

I also have a presentation where I demonstrate how to:

-

Model segmental bridges in Autodesk software.

-

Extract construction-ready data for on-site fabrication of segments.

-

Automatically generate 2D drawings from the 3D model, suitable for production and documentation.

https://www.autodesk.com/autodesk-university/class/Automated-Linear-Structural-BIM-2019