Hi Forum,

I’ve got a drawing that contains 3000 complex/overlapping pipe network segments and I need to calculate cut/fill quantities.

My idea was the following in dynamo:

Import pipenetworks → Convert centerline to curve → Lower curves to the theoretical ditch depth → Convert to deature lines → Add property set data to the feature lines with the pipes width information (The pipe width varies a lot it will affect the quantaties of the ditch cut/fill)

And continue in civil 3d by:

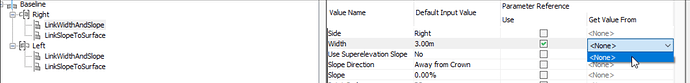

Adding all the feature lines as baseline to a corridor → Assign the assembly → Let the subassembly ‘‘LinkWidthAndSlop’’ look at the property set data of the featureline baseline to define the corresponing ditch width in that corridor region → Extract all datum link codes to create a theoretical cut model wich i can use in quantity analys.

I’ve ran out of luck since a subassembly parameter value cant fetch data from property sets.

Also tried using the Subassembly.SetParameterValue node, but that only seems to statically change the value of the parameter. Is this node really a static value?

One other idea: Assign all the feature lines as baseline to the corridor → Apply assembly → Read all regions in dynamo and fetch its baseline → read out the property set data → somehow apply that width value to the width target. (but i have not found a way to make that work in dynamo yet)

Does anyone have any clever ideas to make this workflow work somehow? I’m out of ideas and do not look foreward doing this by hand.

Thanks for the response @zachri.jensen

- Yes, i am using Civil 3D 2025.1

- Yes, trench width is constant from the outer wall of the pipe.

- No, there are some arc segments

Basing the baseline on outer wall might be a good idea, altough im not sure how line direction will impact corridor creation. Could be possible that regions will flip.

That’s a good point. I was thinking that you could create the alignments and profiles for the pipes, then create the corridors and add the alignment/profile baselines and set the surface targets (all using Dynamo). The direction part will be tricky if the pipes aren’t grouped into runs with consistent direction, unless you just make an individual corridor for each pipe.

With all that said, could you save a few steps and just do all the work in Dynamo instead of building corridors? Basically, you’d be creating your own “corridor” by computing the cross sections at an increment and then lofting a solid. You could do this for each pipe, which avoids the direction issue. Here’s an example I put together, maybe it gives you some inspiration!

Note that this is making a big assumption that you’re always in a cut condition. If you alternate between cut/fill, this would get more complicated such that building corridors might make more sense.

TrenchExcavation.dyn (83.3 KB)

2 Likes

I agree, if you are only getting quantities, it seems like you would want to keep everything inside of dynamo. I would be happy to help if you want to send me a private message with some sample files, etc.

Also, you last step is going to be a boolean subtraction of all the pipe solids from your trench solid.

2 Likes

Hi, Thanks for both of your comments. Sorry for the delayed respons.

Thanks for the insights on how to make it work in dynamo, very helpfull. Although i would like to do this in dynamo exclusively i will eventualy need a civil 3d surface from the bottom of the trench. If thats by making corridors or solids doesnt matter to me, i need to get this to work.

The other thing is that, theoreticaly, there will be multiple adjecent pipes close to eachother, wich means multiple adjecent trenches. There will be overlap in solids when using the workflow above. Unless i can easily union the solids somehow and extract the bottom part to civil surface.

The fill quantities will be more complex because i need to model different kinds of soil materials in the trench with varying heights. Thats why i am aiming on a more civil 3d direction since i can do this rather quick by using volume analys.

I am gonna be testing out some things tomorrow, will update when i progress in the workflow. Feel free to suggest something anytime about the things i stated above.